Zirconium tetrachloride Zrcl4

1,Breif introduction:

At room temperature, Zirconium tetrachloride is a white crystalline powder with a lattice structure belonging to the cubic crystal system. The sublimation temperature is 331 ℃ and the melting point is 434 ℃. The gaseous zirconium tetrachloride molecule has a tetrahedral structure. In the solid state, zirconium tetrachloride associates with each other to form a serrated chain structure with ZrCl6 octahedron as the unit.

The chemical properties of zirconium tetrachloride are similar to titanium tetrachloride, but its activity is slightly weaker than titanium tetrachloride. Zirconium tetrachloride is easily hydrolyzed and may generate zirconium oxychloride and hydrochloric acid in aqueous solutions or in humid air. Zirconium tetrachloride is soluble in many organic solvents, such as alcohol, ether, and so on. Zirconium tetrachloride can react with active metals such as sodium, magnesium, calcium, etc., and can be reduced to metals or low valent chlorides depending on different conditions. ZrCl4 is the precursor of most zirconium compounds. It can be used for various specific purposes, mainly concentrated in materials science, or as a catalyst. It can react strongly with water, has strong hygroscopicity, and is easily hydrolyzed.

Appearance and Description:

Cas No.:10026-11-6

Zirconium tetrachloride is a white, shiny crystal or powder that is prone to deliquescence.

Chinese name: zirconium tetrachloride

Chemical formula: Zrcl4

Molecular weight: 233.20

Density: relative density (water=1) 2.80

Steam pressure: 0.13kPa (190 ℃)

Melting point: > 300 ℃

Boiling point: 331 ℃/sublimation

Nature:

Solubility: Soluble in cold water, ethanol, ether, insoluble in benzene, carbon tetrachloride, and carbon disulfide. Zirconium tetrachloride emits smoke in humid air and undergoes strong hydrolysis upon contact with water. The hydrolysis is incomplete, and the hydrolysis product is zirconium oxychloride:

ZrCl4+H2O─→ZrOCl2+2HCl

2.Classification and production process of zirconium tetrachloride

Classification of zirconium tetrachloride

Industrial grade crude zirconium tetrachloride, industrial grade refined zirconium tetrachloride, atomic level crude zirconium tetrachloride, atomic level refined zirconium tetrachloride, and electronic grade zirconium tetrachloride.

1) Differences between industrial grade and atomic level zirconium tetrachloride

Industrial grade zirconium tetrachloride for separation of zirconium and hafnium; The atomic energy level of zirconium tetrachloride has undergone a zirconium hafnium separation process.

2) Differences between crude and refined zirconium tetrachloride

Crude zirconium tetrachloride has not been purified for iron removal; The refined zirconium tetrachloride has undergone a purification and iron removal process.

3) Electronic grade zirconium tetrachloride

Mainly used in the electronics industry.

Production process of zirconium tetrachloride

Process 1

Zircon sand desilication zirconia chlorination industrial grade coarse zirconium tetrachloride purification industrial grade fine zirconium tetrachloride;

Process 2

Zircon sand – alkali melting – zirconium oxychloride – zirconium hafnium separation – atomic energy level zirconia – chlorination – atomic energy level coarse zirconium tetrachloride – atomic energy level fine zirconium tetrachloride;

Process 3

Zircon sand – chlorination – industrial grade coarse zirconium tetrachloride – purification of industrial grade fine zirconium tetrachloride;

Process 4

Zircon sand – desilication zirconia – chlorination – industrial grade crude zirconium tetrachloride – purification – industrial grade refined zirconium tetrachloride – pyrometallurgical separation of zirconium and hafnium – atomic level refined zirconium tetrachloride.

Process 5

Zircon sand – chlorination – industrial grade coarse zirconium tetrachloride – purification – industrial grade fine zirconium tetrachloride Fire separation of zirconium and hafnium – atomic level refined zirconium tetrachloride.

Quality requirements for zirconium tetrachloride

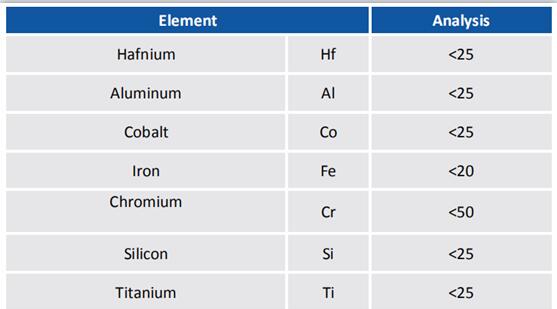

Impurity content: hafnium, iron, silicon, titanium, aluminum, nickel, manganese, chromium;

Main content: zirconia or metallic zirconia;

Purity: 100% minus impurity purity;

The content of insoluble substances;

Electronic grade zirconium tetrachloride

Purity 99.95%

Industrial grade zirconium tetrachloride

1) Crude zirconium tetrachloride

2) Refined zirconium tetrachloride

Atomic Energy Level Zirconium Tetrachloride

1) Crude zirconium tetrachloride

2) Refined zirconium tetrachloride

|

Product grade |

Refined zirconium tetrachloride |

Note |

||

| Zr min | 37.5 | |||

|

Chemical composition (mass fraction)/% |

Impurity content not greater than |

Al |

0.0025 |

After purification |

|

Fe |

0.025 |

|||

|

Si |

0.010 |

|||

|

Ti |

0.005 |

|||

|

Ni |

0.002 |

|||

|

Mn |

0.005 |

|||

|

Cr |

0.005 |

|||

3 Others

3.1 Factors affecting the production of zirconium tetrachloride

Purity of raw materials, particle distribution, component distribution ratio, chlorine gas flow rate, chlorination furnace device, reaction temperature;

3.2 Application of Zirconium Tetrachloride and Selection of Downstream Products

Industrial grade sponge zirconium; Nuclear grade sponge zirconium; Zirconium oxychloride; Yttrium zirconium powder; Other zirconium materials;

533 Comprehensive utilization of waste materials in the production process of zirconium tetrachloride

3.4 Manufacturers of zirconium tetrachloride

3.5 Market for zirconium tetrachloride

3.6 New technologies, equipment, and processes in the production process of zirconium tetrachloride