What is hafnium tetrachloride used for?

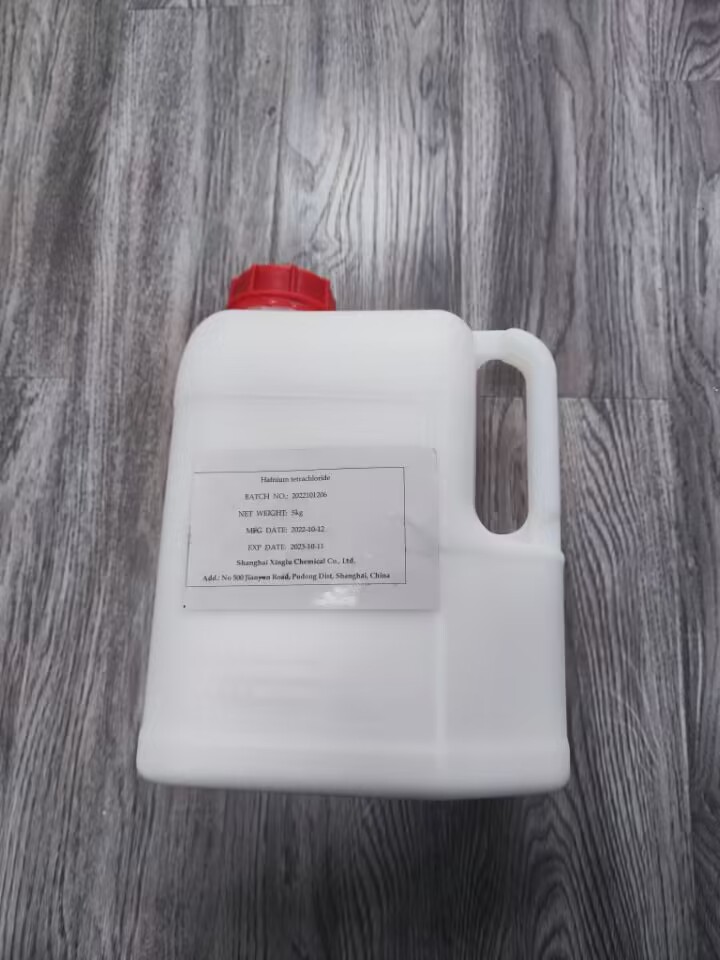

Hafnium tetrachloride, also known as hafnium(IV) chloride or HfCl4, is a compound with CAS number 13499-05-3. It is characterized by high purity, usually 99.9% to 99.99%, and low zirconium content, ≤0.1%. The color of hafnium tetrachloride particles is usually white or off-white, with a density of 3.89 g/cubic centimeter and a melting point of 432°C. Notably, it breaks down in water, indicating that it reacts with moisture.

Hafnium tetrachloride can be used as a precursor in the production of ultra-high temperature ceramics. Known for their excellent thermal stability, these ceramics are used in a variety of high-temperature applications, such as thermal protection systems in the aerospace industry and the manufacture of cutting tools and crucibles. The compound’s ability to withstand extreme temperatures makes it an important component in the development of materials for advanced technologies and industrial uses.

Moreover, hafnium tetrachloride plays a vital role in the field of high-power LEDs. It is used in the production of phosphors, which are critical to the functionality of LEDs. Phosphors are materials that emit light when exposed to radiation and are integral to LED performance by converting blue light into other colors, thereby improving the overall efficiency and color quality of lighting.

High-purity hafnium tetrachloride can be customized to reduce zirconium content to 200ppm, ensuring it is suitable for demanding applications where impurities may adversely affect the final product. This level of purity is critical for the successful synthesis of advanced materials, where precise control of chemical composition is crucial.

In summary, hafnium tetrachloride, with its excellent purity and unique properties, has become an important precursor for the production of ultra-high temperature ceramics and plays an important role in the advancement of high-power LED technology. Its versatility and reactivity make it an integral component in the development of materials for cutting-edge industrial and technical applications.