Effect of Rare Earth on Aluminum and Aluminum Alloys

The application of rare earth in casting aluminum alloy was carried out earlier abroad. Although China started the research and application of this aspect only in the 1960s, it has developed rapidly. A lot of work has been done from mechanism research to practical application, and some achievements have been made.With the addition of rare earth elements, the mechanical properties, casting properties and electrical properties of aluminum alloys have been greatly improved.In the field of new materials, the rich optical, electrical and magnetic properties of rare earth elements also play an important role in making rare earth permanent magnetic materials, rare earth light-emitting materials, rare earth hydrogen storage materials, etc.

◆ ◆ Action mechanism of rare earth in aluminum and aluminum alloy ◆ ◆

Rare earth has high chemical activity, low potential and special electron layer arrangement, and can interact with almost all elements.Rare earths commonly used in aluminum and aluminum alloys include La (lanthanum), Ce (cerium), Y (yttrium) and Sc (scandium). They are often added into aluminum liquid with modifiers, nucleating agents and degassing agents, which can purify the melt, improve the structure, refine the grain, etc.

01 Purification of rare earth

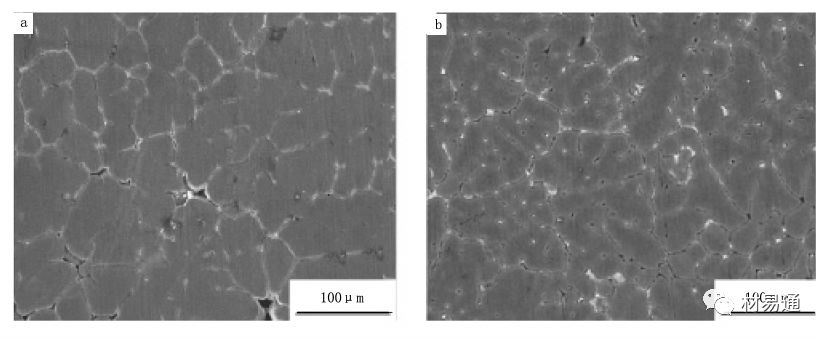

As a large amount of gas and oxide inclusions (mainly hydrogen, oxygen and nitrogen) will be brought in during the melting and casting of aluminum alloy, pinholes, cracks, inclusions and other defects will occur in the casting (see Figure 1a), reducing the strength of aluminum alloy.The purification effect of rare earth is mainly manifested in the obvious reduction of hydrogen content in molten aluminum, the reduction of pinhole rate and porosity (see Figure 1b), and the reduction of inclusions and harmful elements.The main reason is that rare earth has a large affinity with hydrogen, which can absorb and dissolve hydrogen in large quantities and form stable compounds without forming bubbles, thus significantly reducing the hydrogen content and porosity of aluminum;Rare earth and nitrogen form refractory compounds, which are mostly removed in the form of slag in the smelting process, so as to achieve the purpose of purifying aluminum liquid.

Practice has proved that rare earth has the effect of reducing the content of hydrogen, oxygen and sulfur in aluminum and aluminum alloys. Adding 0.1%~0.3% RE in aluminum liquid is helpful to better remove harmful impurities, refine impurities or change their morphology, so as to refine and evenly distribute grains;In addition, RE and harmful impurities with low melting point form binary compounds such as RES, REAs, and REPb, which are characterized by high melting point, low density, and stable chemical properties, and can be floated up to form slag and removed, thus purifying aluminum liquid;The remaining fine particles become heterogeneous nuclei of aluminum to refine grains.

Fig. 1 SEM Morphology of 7075 Alloy without RE and w (RE)=0.3%

a. RE is not added;b. Add w (RE)=0.3%

02 Metamorphism of rare earth

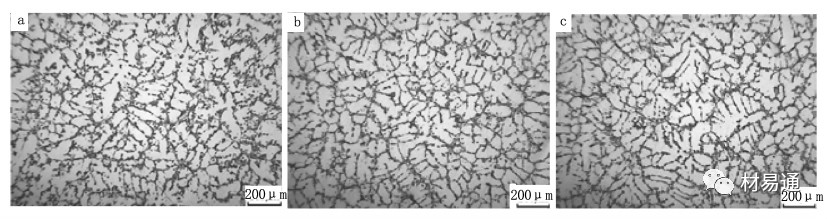

Rare earth modification is mainly manifested in refining grains and dendrites, inhibiting the appearance of coarse lamellar T2 phase, eliminating the coarse massive phase distributed in the primary crystal and forming spherical phase, so that the strip and fragment compounds at the grain boundary are significantly reduced (see Figure 2).Generally, the radius of rare earth atom is larger than that of aluminum atom, and its properties are relatively active. Melting in aluminum liquid is very easy to fill the surface defects of alloy phase, which reduces the surface tension on the interface between new and old phases, and improves the growth rate of crystal nucleus;At the same time, it can also form a surface active film between the grains and the molten liquid to prevent the growth of the generated grains and refine the alloy structure (see Figure 2b).

Fig. 2 Microstructure of Alloys with Different RE Addition

a. RE dosage is 0;b. RE addition is 0.3%;c. RE addition is 0.7%

After adding rare earth elementsαThe grains of (Al) phase began to become smaller, which played a role in refining grainsα(Al) transformed into a small rose or rod shape, when the content of rare earth is 0.3%αThe grain size of (Al) phase is the smallest, and gradually increases with the further increase of rare earth content.Experiments have proved that there is a certain incubation period for rare earth metamorphism, and only when it is kept at a high temperature for a certain period of time, rare earth will play the largest role in metamorphism.In addition, the number of crystal nuclei of the compounds formed by aluminum and rare earth increases greatly when the metal crystallizes, which also makes the alloy structure refined.The research shows that rare earth has good modification effect on aluminum alloy.

03 Microalloying effect of rare earth

Rare earth mainly exists in aluminum and aluminum alloys in three forms: solid solution in the matrixα(Al);Segregation at phase boundary, grain boundary and dendrite boundary;Solid solution in or in the form of compound.The strengthening effects of rare earth in aluminum alloys mainly include grain refinement strengthening, finite solution strengthening and the second phase strengthening of rare earth compounds.

The existence form of rare earth in aluminum and aluminum alloy is closely related to its addition amount. Generally, when RE content is less than 0.1%, the role of RE is mainly fine grain strengthening and finite solution strengthening;When RE content is 0.25%~0.30%, RE and Al form a large number of spherical or short rod like intermetallic compounds, which are distributed in the grain or grain boundary, and a large number of dislocations, fine grain spheroidized structures and dispersed rare earth compounds appear, which will produce micro alloying effects such as second phase strengthening.

◆ ◆ Effect of rare earth on properties of aluminum and aluminum alloy ◆◆

01 Effect of rare earth on comprehensive mechanical properties of alloy

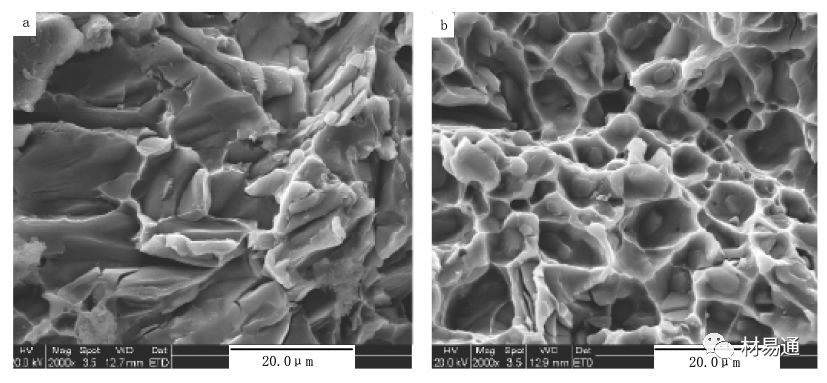

The strength, hardness, elongation, fracture toughness, wear resistance and other comprehensive mechanical properties of the alloy can be improved by adding appropriate amount of rare earth.0.3% RE is added to cast aluminum ZL10 series alloyσbfrom 205.9 MPa to 274 MPa, and HB from 80 to 108;Adding 0.42% Sc to 7005 alloyσbincreased from 314MPa to 414MPa,σ0.2increased from 282MPa to 378MPa, the plasticity increased from 6.8% to 10.1%, and the high-temperature stability was significantly enhanced;La and Ce can significantly improve the superplasticity of the alloy. Adding 0.14%~0.64% La to Al-6Mg-0.5Mn alloy increases the superplasticity from 430% to 800%~1000%;A systematic study of Al Si alloy shows that the yield strength and ultimate tensile strength of the alloy can be greatly improved by adding an appropriate amount of Sc.Fig. 3 shows the SEM appearance of tensile fracture of Al-Si7-Mg0.8alloy, which indicates that it is a typical brittle cleavage fracture without RE, while after 0.3% RE is added, obvious dimple structure appears in the fracture, which indicates that it has good toughness and ductility.

Fig. 3 Tensile Fracture Morphology

a. Not joined RE;b. Add 0.3% RE

02 Effect of Rare Earth on High Temperature Properties of Alloys

Adding a certain amount of rare earth into aluminum alloy can effectively improve the high-temperature oxidation resistance of aluminum alloy.Adding 1%~1.5% mixed rare earth to the cast Al Si eutectic alloy increases the high temperature strength by 33%, the high temperature rupture strength (300 ℃, 1000 hours) by 44%, and the wear resistance and high temperature stability are significantly improved;Adding La, Ce, Y and mischmetal to cast Al Cu alloys can improve the high-temperature properties of the alloys;The rapidly solidified Al-8.4% Fe-3.4% Ce alloy can work for a long time below 400 ℃, greatly improving the working temperature of aluminum alloy;Sc is added to the Al Mg Si alloy to form Al3Sc particles that are not easy to coarsen at high temperature and cohere with the matrix to pin the grain boundary, so that the alloy maintains an unrecrystallized structure during annealing, and greatly improves the high-temperature properties of the alloy.

03 Effect of Rare Earth on Optical Properties of Alloys

Adding rare earth into aluminum alloy can change the structure of its surface oxide film, making the surface more bright and beautiful.When 0.12%~0.25% RE is added to the aluminum alloy, the reflectivity of the oxidized and colored 6063 profile is up to 92%;When 0.1%~0.3% RE is added to Al Mg cast aluminum alloy, the alloy can obtain the best surface finish and gloss durability.

04 Effect of Rare Earth on Electrical Properties of Alloys

Adding RE to high-purity aluminum is harmful to the conductivity of the alloy, but the conductivity can be improved to a certain extent by adding appropriate RE to industrial pure aluminum and Al Mg Si conductive alloys.The experimental results show that the conductivity of aluminum can be improved by 2%~3% by adding 0.2% RE.Adding a small amount of yttrium rich rare earth into Al Zr alloy can improve the conductivity of the alloy, which has been adopted by most domestic wire factories;Add trace rare earth to high-purity aluminum to make Al RE foil capacitor. When used in 25kV products, the capacitance index is doubled, the capacity per unit volume is increased by 5 times, the weight is reduced by 47%, and the capacitor volume is significantly reduced.

05 Effect of Rare Earth on Corrosion Resistance of Alloy

In some service environments, especially in the presence of chloride ions, alloys are vulnerable to corrosion, crevice corrosion, stress corrosion and corrosion fatigue.In order to improve the corrosion resistance of aluminum alloys, many studies have been carried out. It is found that adding appropriate amount of rare earth to aluminum alloys can effectively improve their corrosion resistance.The samples made by adding different amounts of mixed rare earths (0.1%~0.5%) to aluminum were soaked in brine and artificial seawater for three consecutive years. The results show that adding a small amount of rare earths to aluminum can improve the corrosion resistance of aluminum, and the corrosion resistance in brine and artificial seawater is 24% and 32% higher than that of aluminum, respectively;Using chemical vapor method and adding rare earth multi-component penetrant (La, Ce, etc.), a layer of rare earth conversion film can be formed on the surface of 2024 alloy, making the surface electrode potential of aluminum alloy tend to be uniform, and improving the resistance to intergranular corrosion and stress corrosion;Adding La to high Mg aluminum alloy can significantly improve the anti marine corrosion ability of the alloy;Adding 1.5%~2.5% Nd to aluminum alloys can improve the high-temperature performance, air tightness and corrosion resistance of the alloys, which are widely used as aerospace materials.

◆ ◆ Preparation technology of rare earth aluminum alloy ◆ ◆

Rare earth is mostly added in the form of trace elements in aluminum alloys and other alloys. Rare earth has high chemical activity, high melting point, and is easy to be oxidized and burned at high temperatures. This has caused certain difficulties in the preparation and application of rare earth aluminum alloys.In the long-term experimental research, people continue to explore the preparation methods of rare earth aluminum alloys.At present, the main production methods for preparing rare earth aluminum alloys are mixing method, molten salt electrolysis method and aluminothermic reduction method.

01 Mixing method

Mixed melting method is to add rare earth or mixed rare earth metal into high-temperature aluminum liquid in proportion to make master alloy or application alloy, and then melt the master alloy and the remaining aluminum according to the calculated allowance together, fully stir and refine.

02 Electrolysis

The molten salt electrolysis method is to add rare earth oxide or rare earth salt into the industrial aluminum electrolytic cell and electrolyze with aluminum oxide to produce rare earth aluminum alloy.Molten salt electrolysis method has developed relatively fast in China. Generally, there are two ways, namely, liquid cathode method and electrolytic eutectoid method. At present, it has been developed that rare earth compounds can be directly added to industrial aluminum electrolytic cells, and rare earth aluminum alloys can be produced by electrolysis of chloride melts by eutectoid method.

03 Aluminothermic reduction method

Because aluminum has a strong reduction ability, and aluminum can form a variety of intermetallic compounds with rare earth, aluminum can be used as a reducing agent to prepare rare earth aluminum alloys.The main chemical reactions are shown in the following formula:

RE2O3 + 6Al→2REAl2 + Al2O3

Among them, rare earth oxide or rare earth rich slag can be used as rare earth raw materials;The reducing agent can be industrial pure aluminum or silicon aluminum;The reduction temperature is 1400 ℃~1600 ℃.In the early stage, it was carried out under the condition of the existence of heating agent and flux, and high reduction temperature would cause many problems;In recent years, researchers have developed a new aluminothermic reduction method. At a lower temperature (780 ℃), the aluminothermic reduction reaction is completed in the system of sodium fluoride and sodium chloride, which avoids the problems caused by the original high temperature.

◆ ◆ Application progress of rare earth aluminum alloy ◆ ◆

01 Application of rare earth aluminum alloy in power industry

Due to the advantages of good conductivity, large current carrying capacity, high strength, wear resistance, easy processing and long service life, rare earth aluminum alloy can be used to manufacture cables, overhead transmission lines, wire cores, slide wires and thin wires for special purposes.Adding a small amount of RE in the Al Si alloy system can improve the conductivity, which is because the silicon in the aluminum alloy is an impurity element with a high content, which has a greater impact on the electrical properties. Adding an appropriate amount of rare earth can improve the existing morphology and distribution of silicon in the alloy, which can effectively improve the electrical properties of aluminum;Adding a small amount of yttrium or yttrium rich mixed rare earth into the heat-resistant aluminum alloy wire can not only maintain good high-temperature performance but also improve the conductivity;Rare earth can improve the tensile strength, heat resistance and corrosion resistance of aluminum alloy system. Cables and conductors made of rare earth aluminum alloy can increase the span of cable tower and extend the service life of cables.

02 Application of rare earth aluminum alloy in construction industry

6063 aluminum alloy is the most widely used in the construction industry. Adding 0.15%~0.25% rare earth can significantly improve the as cast structure and processing structure, and can improve the extrusion performance, heat treatment effect, mechanical properties, corrosion resistance, surface treatment performance and color tone.It is found that rare earth is mainly distributed in 6063 aluminum alloyα-Al neutralizes the phase boundary, grain boundary and interdendritic, and they are dissolved in compounds or exist in the form of compounds to refine the dendrite structure and grains, so that the size of the undissolved eutectic and the size of the dimple in the dimple area become significantly smaller, the distribution is uniform, and the density increases, so that the various properties of the alloy are improved to varying degrees. For example, the strength of the profile is increased by more than 20%, the elongation is increased by 50%, and the corrosion rate is reduced by more than twice,The thickness of the oxide film increases by 5%~8%, and the coloring property increases by about 3%.Therefore, RE-6063 alloy building profiles are widely used.

03 Application of rare earth aluminum alloy in daily products

Adding trace rare earth to pure aluminum and Al Mg series aluminum alloys for daily use aluminum products can significantly improve the mechanical properties, deep drawing property and corrosion resistance.The daily necessities such as aluminum pots, aluminum pans, aluminum plates, aluminum lunch boxes, aluminum furniture supports, aluminum bicycles, and home appliance parts made of Al Mg RE alloy have more than twice the corrosion resistance, 10%~15% weight reduction, 10%~20% yield increase, 10%~15% production cost reduction, and better deep drawing and deep processing performance compared with aluminum alloy products without rare earth.At present, the daily necessities of rare earth aluminum alloy have been widely used, and the products have increased significantly, and are sold well in the domestic and foreign markets.

04 Application of rare earth aluminum alloy in other aspects

Adding a few thousandths of rare earth in the most widely used Al Si series casting alloy can significantly improve the machining performance of the alloy. Many brands of products have been used in aircraft, ships, automobiles, diesel engines, motorcycles and armored vehicles (piston, gearbox, cylinder, instrumentation and other parts).In research and application, it is found that Sc is the most effective element to optimize the structure and properties of aluminum alloys. It has strong dispersion strengthening, grain refinement strengthening, solution strengthening and microalloy strengthening effects on aluminum, and can improve the strength, hardness, plasticity, toughness, corrosion resistance, heat resistance, etc. of alloys.Sc Al series alloys have been used in high-tech industries such as aerospace, ships, high-speed trains, light vehicles, etc.C557Al Mg Zr Sc series scandium aluminum alloy developed by NASA has high strength and high temperature and low temperature stability and has been applied to aircraft fuselage and aircraft structural parts;The 0146Al Cu Li Sc alloy developed by Russia has been applied to the cryogenic fuel tank of spacecraft.

From Volume 33, Issue 1 of Rare Earth by Wang Hui, Yang An and Yun Qi