Application of Rare Earth Oxide in MLCC

Ceramic formula powder is the core raw material of MLCC, accounting for 20%~45% of the cost of MLCC. In particular, high-capacity MLCC has strict requirements on the purity, particle size, granularity and morphology of ceramic powder, and the cost of ceramic powder accounts for a relatively higher proportion. MLCC is an electronic ceramic powder material formed by adding modified additives to barium titanate powder, which can be directly used as a dielectric in MLCC.

Rare earth oxides are important doping components of MLCC dielectric powders. Although they account for less than 1% of MLCC raw materials, they can play an important role in adjusting ceramic properties and effectively improving the reliability of MLCC. They are one of the indispensable important raw materials in the development process of high-end MLCC ceramic powders.

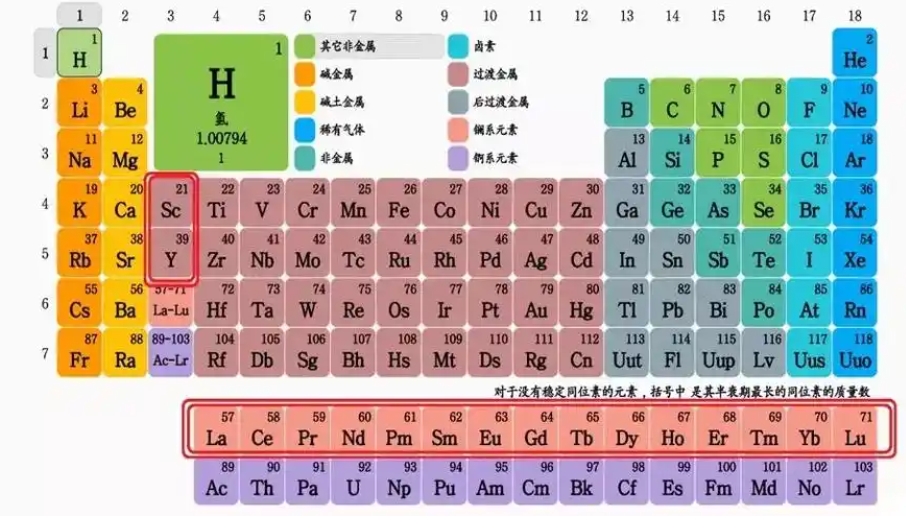

1. What are rare earth elements? Rare earth elements, also known as rare earth metals, are a general term for lanthanide elements and rare earth element groups. They have special electronic structures and physical and chemical properties, and their unique electrical, optical, magnetic, and thermal properties are known as the treasure trove of new materials.

Rare earth elements are divided into: light rare earth elements (with smaller atomic numbers): scandium (Sc), yttrium (Y), lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm) and europium (Eu); heavy rare earth elements (with larger atomic numbers): gadolinium (Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), lutetium (Lu).

Rare earth oxides are widely used in ceramics, mainly cerium oxide, lanthanum oxide, neodymium oxide, dysprosium oxide, samarium oxide, holmium oxide, erbium oxide, etc. Adding a small amount or trace amount of rare earth to ceramics can greatly change the microstructure, phase composition, density, mechanical properties, physical and chemical properties and sintering properties of ceramic materials.

2. Application of rare earth in MLCC Barium titanate is one of the main raw materials for manufacturing MLCC. Barium titanate has excellent piezoelectric, ferroelectric and dielectric properties. Pure barium titanate has a large capacity temperature coefficient, high sintering temperature and large dielectric loss, and is not suitable for direct use in the manufacture of ceramic capacitors.

Research has shown that the dielectric properties of barium titanate are closely related to its crystal structure. Through doping, the crystal structure of barium titanate can be regulated, thereby improving its dielectric properties. This is mainly because fine-grained barium titanate will form a shell-core structure after doping, which plays an important role in improving the temperature characteristics of capacitance.

Doping rare earth elements into the barium titanate structure is one of the ways to improve the sintering behavior and reliability of MLCC. Research on rare earth ion doped barium titanate can be traced back to the early 1960s. The addition of rare earth oxides reduces the mobility of oxygen, which can enhance the dielectric temperature stability and electrical resistance of dielectric ceramics, and improve the performance and reliability of products. Commonly added rare earth oxides include: yttrium oxide (Y2O3), dysprosium oxide (Dy2O3), holmium oxide (Ho2O3), etc.

The radius size of rare earth ions has a crucial impact on the position of the Curie peak of barium titanate based ceramics. Doping of rare earth elements with different radii can alter the lattice parameters of crystals with shell core structures, thereby changing the internal stresses of the crystals. Doping of rare earth ions with larger radii leads to the formation of pseudocubic phases in the crystals and residual stresses inside the crystals; The introduction of rare earth ions with smaller radii also generates less internal stress and suppresses phase transition in the shell core structure. Even with small amounts of additives, the characteristics of rare earth oxides, such as particle size or shape, can significantly affect the overall performance or quality of the product. High performance MLCC is constantly developing towards miniaturization, high stacking, large capacity, high reliability, and low cost. The world’s most cutting-edge MLCC products have entered the nanoscale, and rare earth oxides, as important doping elements, should have nanoscale particle size and good powder dispersion.