Important rare earth compounds: What are the uses of yttrium oxide powder?

Important rare earth compounds: What are the uses of yttrium oxide powder?

Rare earth is an extremely important strategic resource, and it has an irreplaceable role in industrial production. Automobile glass, nuclear magnetic resonance, optical fiber, liquid crystal display, etc. are inseparable from the addition of rare earth. Among them, yttrium (Y) is one of the rare earth metal elements and is a kind of gray metal. However, due to its high content in the earth’s crust, the price is relatively cheap and it is widely used.In the current social production, it is mainly used in the state of yttrium alloy and yttrium oxide.

Yttrium Metal

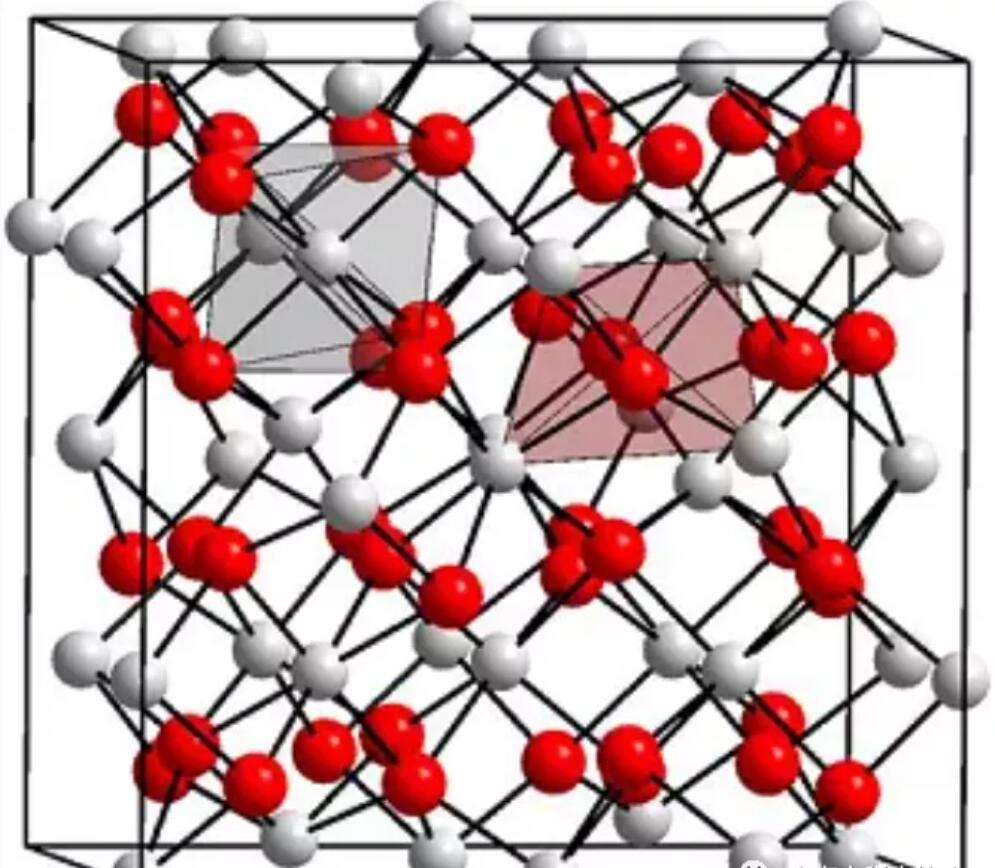

Among them, yttrium oxide (Y2O3) is the most important yttrium compound. It is insoluble in water and alkali, soluble in acid, and has an appearance of white crystalline powder (the crystal structure belongs to the cubic system). It has very good chemical stability and is under vacuum. Low volatility, high heat resistance, corrosion resistance, high dielectric, transparency (infrared) and other advantages, so it has been applied in many fields. What are the specific ones?Let’s take a look.

The crystal structure of yttrium oxide

01 Synthesis of yttrium stabilized zirconia powder. The following phase changes will occur during the cooling of pure ZrO2 from high temperature to room temperature: cubic phase (c) → tetragonal phase (t) → monoclinic phase (m), where t will occur at 1150°C →m phase change, accompanied by a volume expansion of about 5%. However, if the t→m phase transition point of ZrO2 is stabilized to room temperature, the t→m phase transition is induced by stress during loading.Due to the volume effect generated by the phase change, a large amount of fracture energy is absorbed, so that the material exhibits an abnormally high fracture energy, so that the material exhibits an abnormally high fracture toughness, resulting in phase transformation toughness, and high toughness and high wear resistance. sex.

To achieve the phase change toughening of zirconia ceramics, a certain stabilizer must be added and under certain firing conditions, the high-temperature stable phase-tetragonal meta-stabilization to room temperature, obtains a tetragonal phase that can be phase-transformed at room temperature. It is the stabilizing effect of stabilizers on zirconia. Y2O3 is the most researched zirconium oxide stabilizer so far.The sintered Y-TZP material has excellent mechanical properties at room temperature, high strength, good fracture toughness, and the grain size of the material in its collective is small and uniform, so it has attracted more attention. 02 Sintering aids The sintering of many special ceramics requires the participation of sintering aids. The role of sintering aids can generally be divided into the following parts: forming a solid solution with the sinter;Prevent crystal form transformation; inhibit crystal grain growth; produce liquid phase. For example, in the sintering of alumina, magnesium oxide MgO is often added as a microstructure stabilizer during the sintering process. It can refine the grains, greatly reduce the difference in grain boundary energy, weaken the anisotropy of grain growth, and inhibit Discontinuous grain growth. Since MgO is highly volatile at high temperatures, in order to achieve good results,Yttrium oxide is often mixed with MgO. Y2O3 can refine the crystal grains and promote sintering densification. 03YAG powder synthetic yttrium aluminum garnet (Y3Al5O12) is a man-made compound, no natural minerals, colorless, Mohs hardness can reach 8.5, melting point 1950 ℃, insoluble in sulfuric acid, hydrochloric acid, nitric acid, hydrofluoric acid, etc. The high temperature solid phase method is a traditional method for preparing YAG powder.According to the ratio obtained in the binary phase diagram of yttrium oxide and aluminum oxide, the two powders are mixed and fired at high temperature, and YAG powder is formed through the solid-phase reaction between the oxides. Under high temperature conditions, in the reaction of alumina and yttrium oxide, the mesophases YAM and YAP will be formed first, and finally YAG will be formed.

The high-temperature solid-phase method for preparing YAG powder has many applications. For example, its Al-O bond size is small and the bond energy is high. Under the impact of electrons, the optical performance is kept stable, and the introduction of rare earth elements can significantly improve the luminescence performance of the phosphor.And YAG can become phosphor by doping with trivalent rare earth ions such as Ce3+ and Eu3+. In addition, YAG crystal has good transparency, very stable physical and chemical properties, high mechanical strength, and good thermal creep resistance. It is a laser crystal material with a wide range of applications and ideal performance.

YAG crystal 04 transparent ceramic yttrium oxide has always been the research focus in the field of transparent ceramics. It belongs to the cubic crystal system and has the isotropic optical properties of each axis. Compared with the anisotropy of transparent alumina, the image is less distorted, so Gradually, it has been valued and developed by high-end lenses or military optical windows. The main characteristics of its physical and chemical properties are: ①High melting point,The chemical and photochemical stability is good, and the optical transparency range is wide (0.23~8.0μm); ②At 1050nm, its refractive index is as high as 1.89, which makes it have a theoretical transmittance of more than 80%; ③Y2O3 has enough to accommodate most The band gap from the larger conduction band to the valence band of the emission level of trivalent rare earth ions can be effectively tailored by the doping of rare earth ions.So as to realize the multi-functionalization of its application; ④The phonon energy is low, and its maximum phonon cut-off frequency is about 550cm-1. The low phonon energy can suppress the probability of non-radiative transition, increase the probability of radiation transition, and improve the luminescence quantum Efficiency; ⑤High thermal conductivity, about 13.6W/(m·K), high thermal conductivity is extremely

important for it as a solid laser medium material.

Yttrium oxide transparent ceramics developed by Japan’s Kamishima Chemical Company

The melting point of Y2O3 is about 2690℃, and the sintering temperature at room temperature is about 1700~1800℃. To make light-transmitting ceramics, it is best to use hot pressing and sintering. Due to its excellent physical and chemical properties, Y2O3 transparent ceramics are widely used and potentially developed, including: missile infrared windows and domes, visible and infrared lenses, high-pressure gas discharge lamps, ceramic scintillators, ceramic lasers and other fields