How much do you know about phosphorus copper?

Phosphorus copper (phosphor bronze) (tin bronze) (tin phosphor bronze) is composed of bronze with added degassing agent phosphorus P content of 0.03-0.35%, tin content of 5-8%, and other trace elements such as iron Fe, zinc Zn, etc. It has good ductility and fatigue resistance, and can be used in electrical and mechanical materials. Its reliability is higher than that of general copper alloy products.

Phosphorus copper, an alloy of phosphorus and copper. Replace pure phosphorus for reducing brass and bronze alloys, and use it as a phosphorus additive in the manufacture of phosphor bronze.

It is divided into 5%, 10%, and 15% levels and can be directly added to molten metal.

Its function is a strong reducing agent, and phosphorus makes bronze harder. Even adding a small amount of phosphorus to copper or bronze can improve its fatigue strength.

To manufacture phosphor copper, it is necessary to press the phosphorus block into the melted copper until the reaction stops.

When the proportion of phosphorus in copper is within 8.27%, it is soluble and forms Cu3P, with a melting point of 707 ℃.

The melting point of phosphorus copper containing 10% phosphorus is 850 ℃, and the melting point of phosphorus copper containing 15% phosphorus is 1022 ℃. When it exceeds 15%, the alloy is unstable.

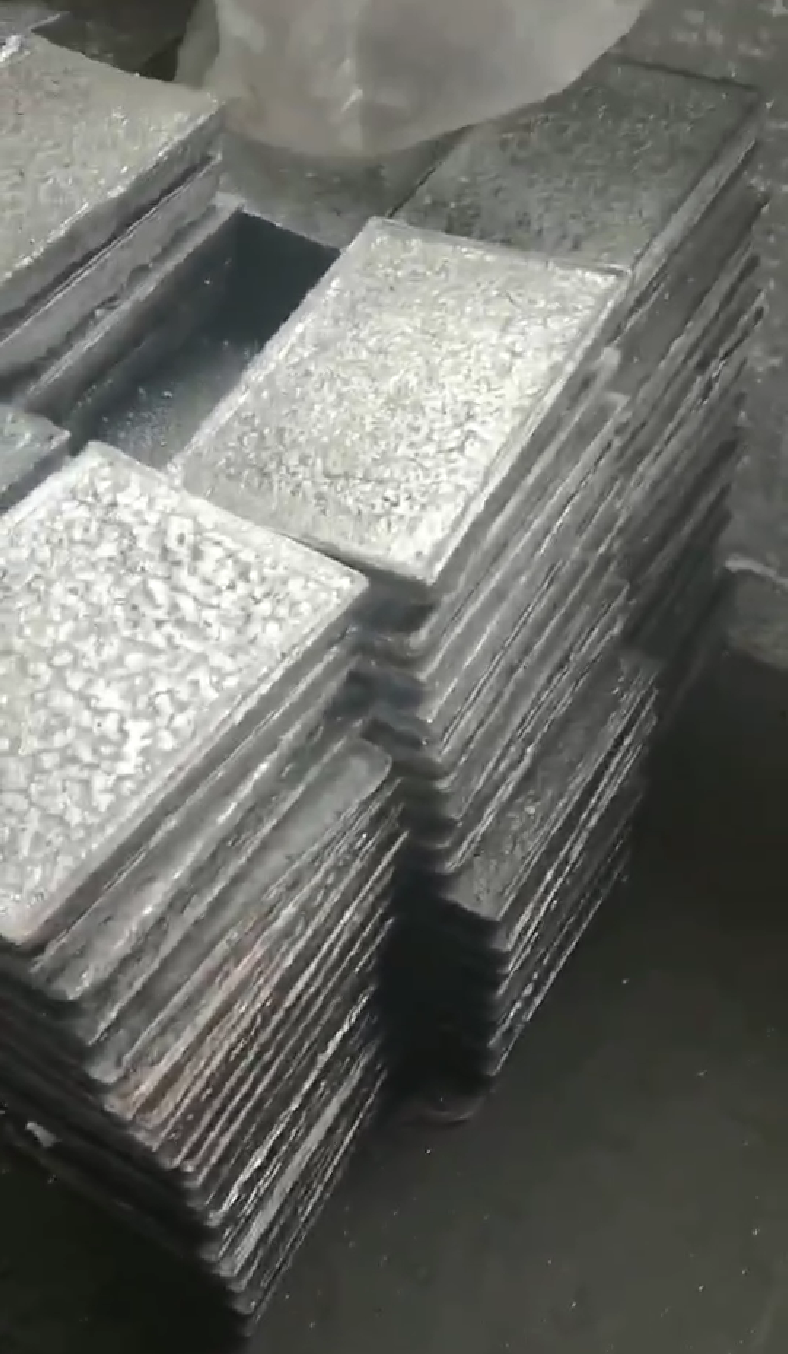

Phosphorus copper is sold in grooved pieces or granules. In Germany, phosphorus zinc is used instead of phosphorus copper to save copper.

MetaIlophos is the name for German phosphozinc containing 20-30% phosphorus.

Commercial copper reduced with phosphorus, with a phosphorus content of less than 0.50%, is also called phosphor copper.

Although the conductivity decreased by about 30%, the hardness and strength increased.

Phosphotin is a mother alloy of tin and phosphorus, used in melting bronze to produce phosphor bronze.

Phosphorus tin usually contains more than 5% phosphorus, but does not contain lead. Its appearance resembles antimony, it is a larger crystal that shines brightly. Sell in sheets.

According to federal regulations in the United States, it is required to contain 3.5% phosphorus and impurities below 0.50%.

Tin phosphorus bronze has higher corrosion resistance, wear resistance, and does not produce sparks during impact. Used for medium speed and heavy-duty bearings, with a maximum operating temperature of 250 ℃.

It has the characteristics of automatic centering, insensitivity to deflection, uniform bearing capacity of the shaft, high bearing capacity, and can withstand radial loads simultaneously. It is self-lubricating and does not require maintenance.

Tin phosphorus bronze is an alloy copper with good electrical conductivity, low heat generation, ensuring safety, and strong fatigue resistance.

The socket spring of tin phosphorus bronze has a hard wired electrical structure, with no rivet connection or friction contact, ensuring good contact, good elasticity, and smooth insertion and removal. This alloy has excellent mechanical processing performance and chip formation.