Four major applications of nano ceria

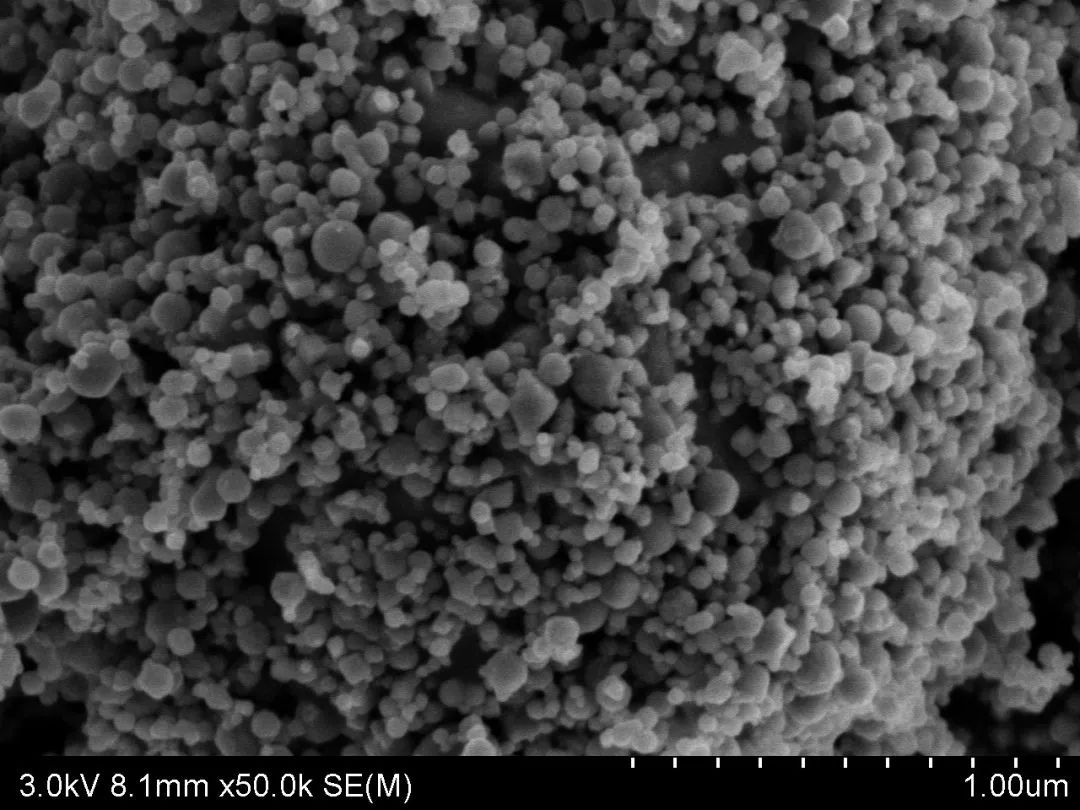

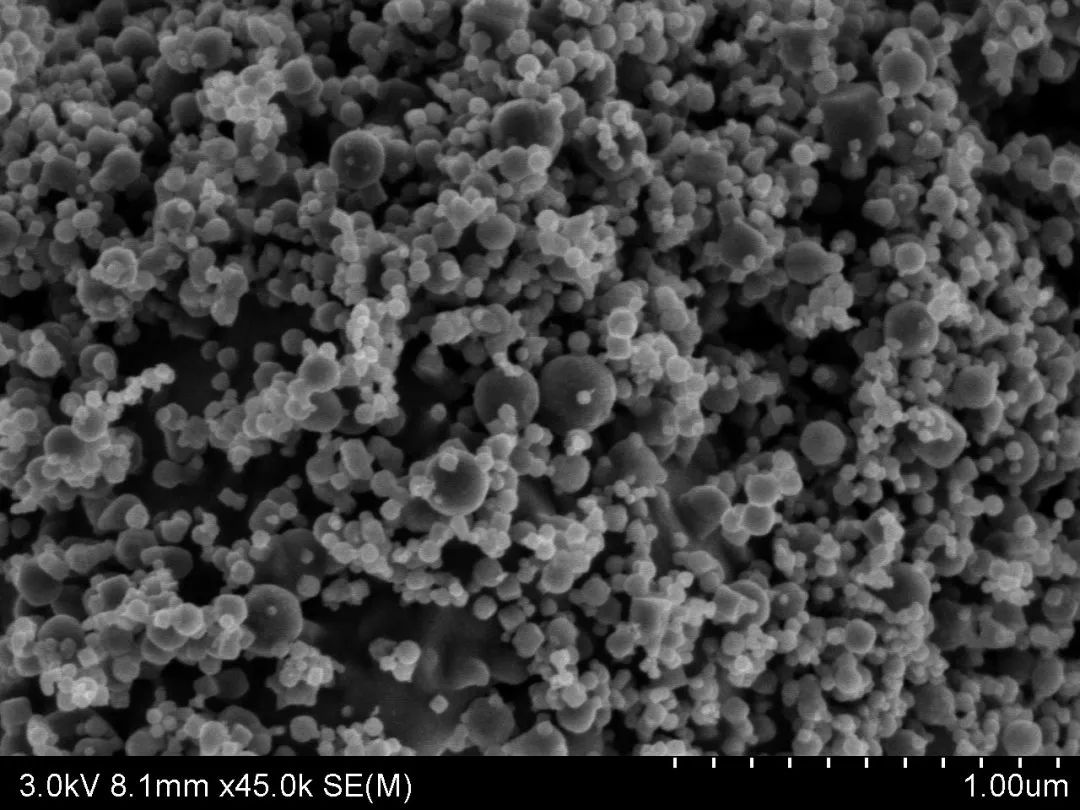

Nano ceria is a cheap and widely used rare earth oxide with small particle size, uniform particle size distribution, and high purity. Insoluble in water and alkali, slightly soluble in acid. It can be used as polishing materials, catalysts, catalyst carriers (additives), automotive exhaust absorbers, ultraviolet absorbers, fuel cell electrolytes, electronic ceramics, etc. Nanoscale ceria can directly affect the performance of materials, such as adding ultrafine nano ceria to ceramics, which can reduce the sintering temperature of ceramics, inhibit lattice growth, and improve the density of ceramics. A large specific surface area can better enhance the catalytic activity of the catalyst. Its variable valence properties give it excellent optoelectronic properties, which can be doped in other semiconductor materials for modification, improving the efficiency of photon migration, and improving the photoexcitation effect of the material.

Applied to UV absorption

According to research, ultraviolet light ranging from 280nm to 320nm can cause skin tanning, sunburn, and even skin cancer in severe cases. Adding nanoscale cerium oxide to cosmetics can reduce the harm of ultraviolet radiation to the human body. Nano cerium oxide has a strong absorption effect on ultraviolet rays and can be used as an ultraviolet absorber for products such as sunscreen cosmetics, car glass, sunscreen fibers, coatings, plastics, etc. Cerium oxide is used in sunscreen cosmetics, which has no characteristic absorption of visible light, good transmittance, and good UV protection effect; Moreover, coating amorphous silicon oxide on cerium oxide can reduce its catalytic activity, thereby preventing the discoloration and deterioration of cosmetics caused by the catalytic activity of cerium oxide.

Applied to catalysts

In recent years, with the improvement of people’s living standards, cars have become increasingly popular in people’s lives. Currently, cars mainly burn gasoline. This cannot avoid the generation of harmful gases. Currently, more than 100 substances have been separated from car exhaust, of which more than 80 are hazardous substances announced by the Chinese environmental protection industry, mainly including carbon monoxide, hydrocarbons, nitrogen oxides, particulate matter (PM), etc. In car exhaust, except for nitrogen, oxygen, and combustion products such as carbon dioxide and water vapor, which are harmless components, all other components are harmful. Therefore, controlling and solving automobile exhaust pollution has become an urgent problem to be solved.

Regarding automotive exhaust catalysts, most of the common metals used by the people in the early days were chromium, copper, and nickel, but their drawbacks were high ignition temperature, susceptibility to poisoning, and poor catalytic activity. Later, precious metals such as platinum, rhodium, palladium, etc. were used as catalysts, which have advantages such as long lifespan, high activity, and good purification effect. However, due to the high price and cost of precious metals, they are also prone to poisoning due to phosphorus, sulfur, lead, etc., making it difficult to promote.

Adding nano ceria to automotive exhaust purification agents has the following advantages compared to adding non nano ceria: the particle specific surface area of nano ceria is large, the coating amount is high, the content of harmful impurities is low, and the oxygen storage capacity is increased; Nano ceria is at the nanoscale, ensuring a high specific surface area of the catalyst in a high-temperature atmosphere, thereby greatly improving catalytic activity; As an additive, it can reduce the amount of platinum and rhodium used, automatically adjust the air fuel ratio and catalytic effect, and improve the thermal stability and mechanical strength of the carrier.

Applied to the steel industry

Due to its special atomic structure and activity, rare earth elements can be used as trace additives in steel, cast iron, aluminum, nickel, tungsten and other materials to eliminate impurities, refine grains and improve material composition, thereby improving the mechanical, physical and processing properties of alloys, and improving the thermal stability and corrosion resistance of alloys. For example, in the steel industry, rare earths as additives can purify molten steel, change the morphology and distribution of impurities in the center of the steel, refine grains, and change structure and performance. The use of nano ceria as a coating and additive can improve the oxidation resistance, hot corrosion, water corrosion, and sulfurization properties of high-temperature alloys and stainless steel, and can also be used as an inoculant for ductile iron.

Applied to other aspects

Nano cerium oxide has many other uses, such as using cerium oxide based composite oxides as electrolytes in fuel cells, which can have sufficiently high oxygen dissociation current density between 500 ℃ and 800 ℃; The addition of cerium oxide during the vulcanization process of rubber can have a certain modifying effect on the rubber; Cerium oxide also plays an important role in fields such as luminescent materials and magnetic materials.